The fastest PCR Thermal Cycler: Next Generation PCR

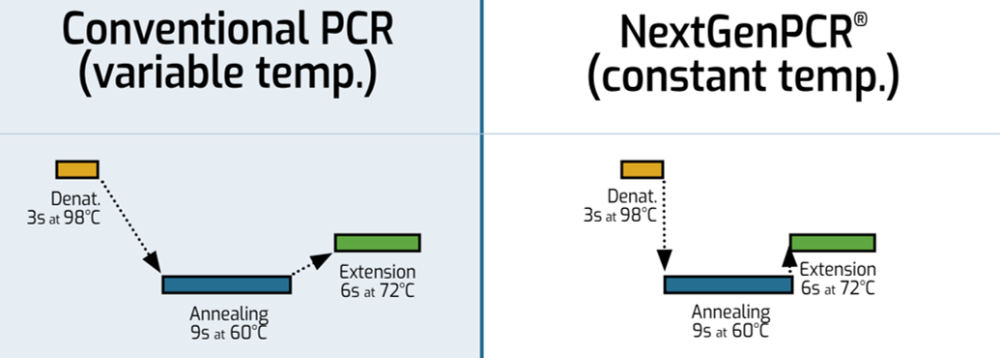

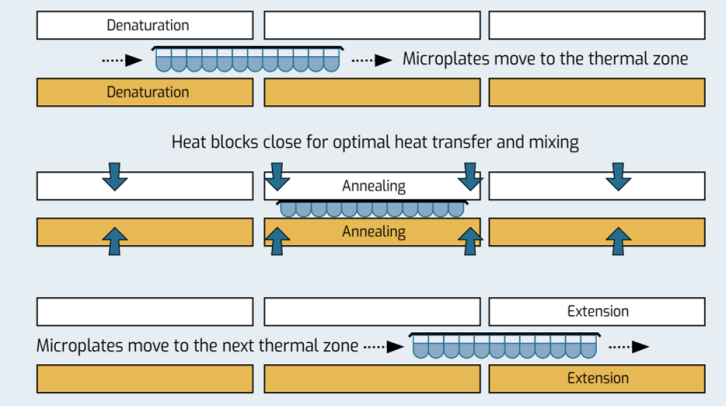

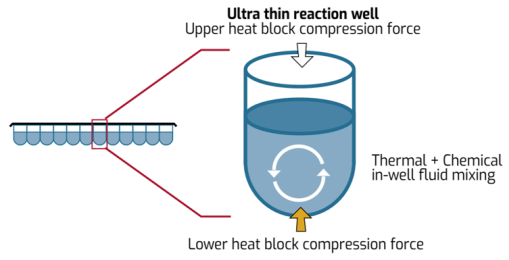

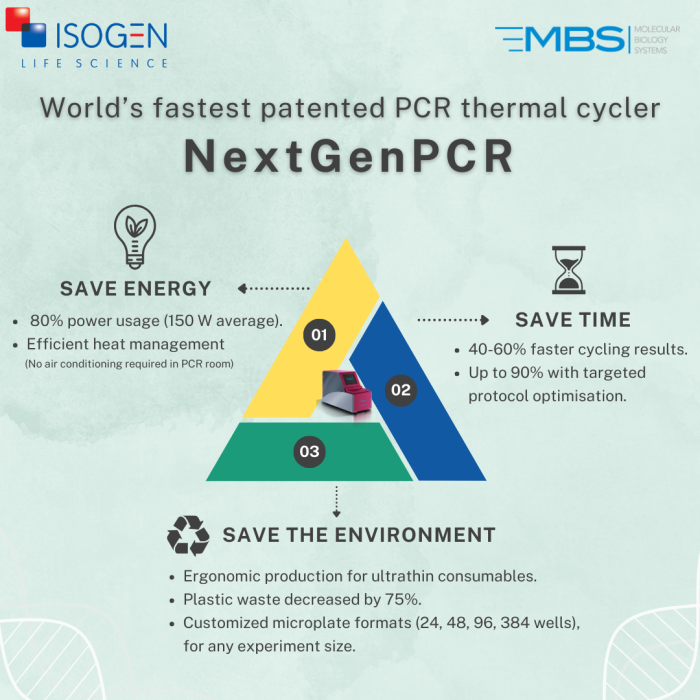

The NextGenPCR® machines use innovative and patented heating technology to perform ultrafast amplification of nucleic acid sequences from biological materials. The high speed makes the NextGenPCR® highly suitable for applications such as nanopore sequencing, detection of infectiousdiseases, next generation, and Sanger sequencing.

- How does it work? Discover why it is the fastest one.

We are the official dealer of the MBS NG-PCR machine in the Netherlands, Belgium, Luxembourg, Spain, Portugal, and the United Kingdom. Did you know that, apart from equipment, Isogen also offers consumables and PCR kits for your NG-PCR machine?